-

Wood

Wood -

Pellets

Pellets -

Briquettes

Briquettes

The combined universal boiler

To all the advantages of the ECOWOOD gasification wood-fired boiler is added the rotating burner with the automatic passage to pellet combustion. This solution guarantees the continuous operation of the heating system, with the possibility of easily integrating manual loading of the wood with the automatic feeding of the pellet burner.

- Integrated anti-condensation system

- Dry and isolated wood combustion chamber

- Pellet burner with rotating combustion chamber in stainless steel

- TOUCH display

- Remote control via the Internet

- Lunga autonomia di funzionamento

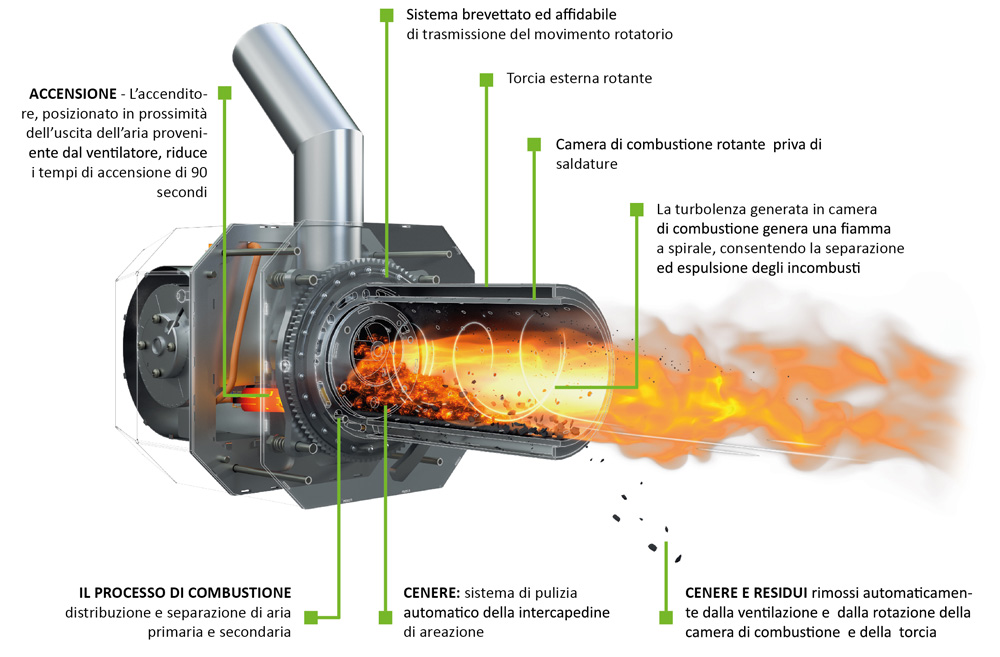

Advantages of the burner with rotating combustion chamber

- The innovative structure of the burner makes it possible to burn even lower quality pellets and agripellet.

- Rotating and self-cleaning combustion chamber. Free of ordinary maintenance, it allows the combustion of pellets of various kinds. Just check the equipment before using it for the winter season.

- Combustion chamber before welding: 4 mm at the thinnest point.

- Designed in modules that allow rapid access to all the components, it allows simple and fast operations both during assembly and maintenance of the burner

- Bearing location: patented system: longitudinal radial load bearings guarantee a sliding burner rotation, without metal / metal abrasions and frictions; the load is transmitted on a minimum of 50 balls (depending on the size of the burner). This results in a long product life (reduced use of the bearings) and no friction between the metal components of the burner.

- Separate distribution of primary and secondary combustion air: patented system that guarantees greater combustion efficiency and the possibility of setting the optimal combustion for different types of pellets. Starting from the external 25 kw power, combined with the constant and high pressure exerted by the internal air supplied by the fan - they allow the ventilation chamber to be kept constantly clean, completely eliminating the need for any manual cleaning with consequent periodic disassembly of the burner.

- Combustion of pellets of various nature and quality it is possible to use pellets of poor quality and / or of agricultural derivation, optimizing the combustion process and regulating the distribution of primary and secondary air.

- Diaphragm of the combustion chamber: an air diaphragm is used in the combustion chamber. This involves reducing the heat transfer in the combustion chamber.

- Ribs in the ventilation chamber: they support the combustion chamber tube, thus reducing heat transmission.

- Loader safety sensor: placed directly in the loading chamber, it guarantees a very high level of safety in the event of burner clogging.

- Completely automatic: it does not require any manual operation or routine maintenance.

* The data are to be considered indicative, calculated on an energy demand equal to 80W / sqm; variations, even significant ones, can be found in the presence of different energy requirements, due to the specific technical and construction characteristics of the building envelope and the winter air-conditioning system.